POLYESTER WEBBING SLING MANUFACTURER

‘Glider’ Polyester Webbing Sling Manufacturer

Need Help in Buying Decision? Call us on 7015580851 and we are here to suggest you which type of Webbing Sling will go best for your work.

"GLIDER" is a registered trademark of Modi Lifting Solutions

Modi Lifting Solutions are the Polyester Webbing Sling Manufacturer with the brand name 'Glider'. Polyester webbing sling are manufactured from double layers of webbing. All of our polyester webbing sling products conform to EN 1492-1:2000 standards and are delivered complete with certificates of conformity. Need something more specific? No problem, we can even design bespoke fittings and create tailored solutions on request.

Polyester Webbing Slings are constructed of nylon synthetic webbing material and offer several attractive features which promote their popularity among rigging products. They are often selected when expensive, highly polished, fragile or delicate loads must be lifted. The softness of the web will not die, deface or scratch loads, while its flexibility assures a firm, secure grip around the item being lifted. The light weight of the material, combined with superb flexibility allows the slings to be quickly and safely handled by riggers. Webbing Slings have the ability to elongate, absorbing and minimizing the effects of heavy shock loads. Nylon slings may stretch 6-8% at rated capacity.

Manufactured slings are to a great degree flexible, can be utilized in Vertical, Choker, Basket hitches and have an Safety Factor of 5:1, which means the breaking strength of the webbing sling is five times higher than the Safe Working Load (SWL).

Features of Polyester Webbing Slings:

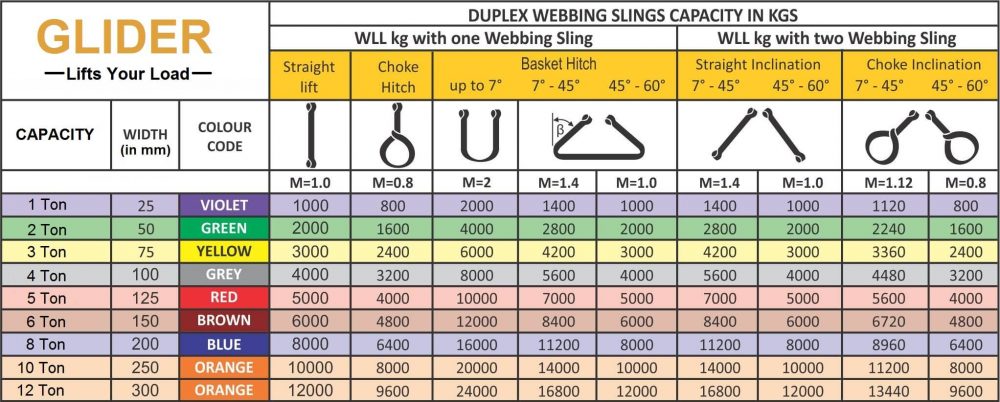

• Color coded for easy identification

• Maximum working temperature 90°c

• Anti-abrasion sleeves and anti-cutting sleeves protection (optional) can be used extra for longer life

Manufactured slings are to a great degree flexible, can be utilized in Vertical, Choker, Basket hitches and have an Safety Factor of 5:1, which means the breaking strength of the webbing sling is five times higher than the Safe Working Load (SWL).

Features of Polyester Webbing Slings:

• Color coded for easy identification

• Maximum working temperature 90°c

• Anti-abrasion sleeves and anti-cutting sleeves protection (optional) can be used extra for longer life

As we are Polyester Webbing Sling Manufacturer, we manufactures Different Types of Polyester Webbing Sling:

Flat Webbing Sling have wide & flat load bearing surface, webbing sling generally comes in 2 Ply and 4 Ply structure, 2 Ply from 1 Ton to 12 Ton and 4 Ply from 16 Ton and above. These are made of number of ply stitched together with reinforced eye loops at both ends. These are the widely used slings for normal load lifting applications.

Round Endless sling are made of polyester yarn and covered with a protective sleeve. They are constructed from a continuous loop of 100% polyester fiber which is covered with a polyester woven jacket to protect the load-bearing fibers from damage and the load-bearing fibers never come in contact with the load as they are protected from cuts and abrasions.

Round Webbing Sling and Round Endless Sling are made of the same process but the only difference is that it is not made in endless shape rather it is made a straight sling with both eye loops on the end but the whole sling is manufactured in the round shape.

Flat Webbing Sling have wide & flat load bearing surface, webbing sling generally comes in 2 Ply and 4 Ply structure, 2 Ply from 1 Ton to 12 Ton and 4 Ply from 16 Ton and above. These are made of number of ply stitched together with reinforced eye loops at both ends. These are the widely used slings for normal load lifting applications.

Round Endless sling are made of polyester yarn and covered with a protective sleeve. They are constructed from a continuous loop of 100% polyester fiber which is covered with a polyester woven jacket to protect the load-bearing fibers from damage and the load-bearing fibers never come in contact with the load as they are protected from cuts and abrasions.

Round Webbing Sling and Round Endless Sling are made of the same process but the only difference is that it is not made in endless shape rather it is made a straight sling with both eye loops on the end but the whole sling is manufactured in the round shape.

Advantages of Using Polyester Webbing Slings:

• Inexpensive and lightweight design makes them attractive to almost any industry or lifting application

• Strong enough to lift heavy loads but will protect expensive and delicate loads from scratching and crushing

• A variety of materials, construction, and specifications can tailor synthetic slings to almost any lifting application

• Inexpensive and lightweight design makes them attractive to almost any industry or lifting application

• Strong enough to lift heavy loads but will protect expensive and delicate loads from scratching and crushing

• A variety of materials, construction, and specifications can tailor synthetic slings to almost any lifting application

Disadvantages of Using Polyester Webbing Slings:

• Synthetic slings have a relatively low heat-resistance and are not recommended for use in high-heat applications

• Special considerations must be made when selecting a synthetic sling to be used in chemical applications. Nylon and polyester slings have different resistance characteristics to acidic and alkaline environments

• Synthetic slings are not as durable as steel slings when it comes to abrasion and cut resistance. Corner protectors or edge guards should be used to protect against cuts and tears.

• Synthetic slings have a relatively low heat-resistance and are not recommended for use in high-heat applications

• Special considerations must be made when selecting a synthetic sling to be used in chemical applications. Nylon and polyester slings have different resistance characteristics to acidic and alkaline environments

• Synthetic slings are not as durable as steel slings when it comes to abrasion and cut resistance. Corner protectors or edge guards should be used to protect against cuts and tears.