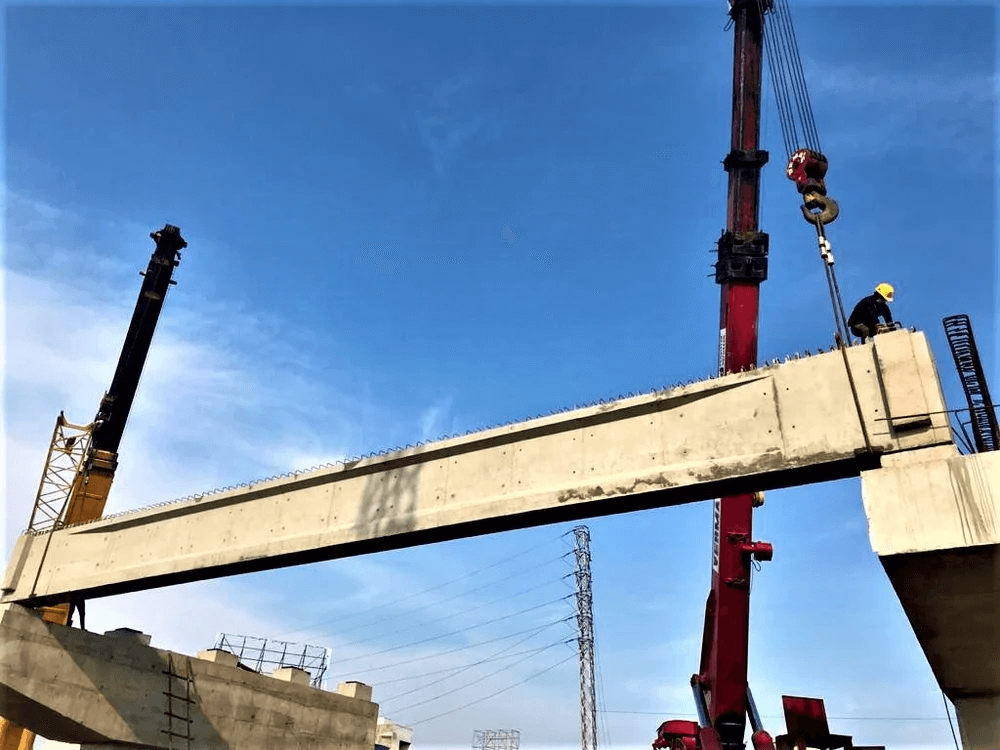

Wire Rope Sling for Lifting Bridge Girder

Wire Rope Sling for Lifting Bridge Girder – Why It’s the Right Choice

When it comes to lifting bridge girders, there is absolutely no scope for compromise. The weights involved are extremely high and any mistake can directly impact safety, project timelines, and costs. That’s why construction and infrastructure contractors across India prefer wire rope slings for lifting bridge girders.

Today, we’ll walk you through why wire rope slings are preferred, what to check before using them, and how Modi Lifting Solutions can support you with high-quality, certified lifting equipment across India.

High Breaking & Working Load Capacity

Wire rope slings are manufactured with strong steel strands that can easily handle heavy bridge girders without deformation.

Excellent Flexibility for Better Contact

Unlike rigid lifting accessories, wire rope slings offer sufficient flexibility and wrap around the girder to provide proper grip and even load distribution.

Resistant to Abrasion & Heat

Construction sites are tough – from sharp edges to hot weather – wire rope slings perform well under these harsh conditions.

Shock Load Handling

Sudden movements during the lift can generate shock loads. Wire rope slings absorb these loads and reduce the risk of failure.

Available in Multiple Leg Configurations

You can select single leg, 2-leg, 3-leg or 4-leg wire rope slings depending on the lifting points available on the girder.

*

*

*

*

*

*

* Using damaged or uncertified slings

* Lifting at improper angles

* Hooking the sling to weak or non-rated lifting points

* Ignoring national safety standards and load testing certificates

Modi Lifting Solutions is one of the trusted manufacturers of Wire Rope Sling for Lifting Bridge Girder. Our slings are quality tested, OEM-approved, and supplied across various government and infrastructure projects all over the country.

Whether you need single leg wire rope slings for pre-cast girders or multi-leg assemblies for large steel girders – we offer fully customised solutions based on your requirements.