CHAIN SLING MANUFACTURER

‘Glider’ Alloy Chain Sling Manufacturer

Need Help in Buying Decision? Call us on 7015580851 and we are here to suggest you which type of Chain Sling will go best for your work.

Modi Lifting Solutions are the Alloy Chain Sling Manufacturer in Grade 80 with the brand name 'Glider'. The Design, Length and End Fittings of Chain Sling can be Customized on demand. All of our Chain Sling products conform to EN standards and are delivered complete with certificates of conformity. Need something more specific? No problem, we can even design bespoke fittings and create tailored solutions on request.

When it comes to toughness and dependability—alloy chain slings are the bulldogs of lifting slings. Chain slings can be used to lift very heavy and bulky loads on a regular or repetitive basis. Chain slings are preferred in high-temperature applications and for lifting heavy-duty loads. Their strength and durability allow them to be used in foundries, steel mills, heavy machine shops, and any other environment where repetitive lifts or harsh conditions would damage or destroy a wire rope sling polyester webbing sling.

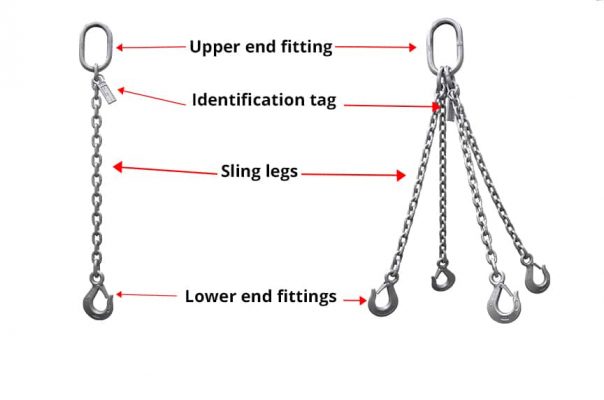

There are many different type of chain sling fittings that enable the users of industrial lifting slings fabricated from chain access to single leg chain slings, 2 leg chain sling, 3 leg chain sling, 4 leg rigging chain sling. The Design Factor for chain slings is a 4:1 ratio, that mean the breaking strength of the sling is four times higher than the Safe Working Load (S.W.L.). Although chain slings have a design factor, the user should never exceed the rated S.W.L.

Chain is produced in different grades. The larger the lifting chain grade number, the stronger the rigging chain. Different types of Chain Sling Grades:

Grade 30 and 40 chain is sold at many hardware stores and is great for barricading parking lots or defending yourself.

Grade 70 transport chains used by trucking and transportation companies are acceptable for use as tie down chains to tie down loads.

Grader 80, 100 & 120 is acceptable for lifting loads. The metal used in Grade 80, 100 and 120 crane rigging slings is designed to stretch and elongate but the most common grade of alloy lifting chain used for lifting loads is Grade 80.

Grade 30 and 40 chain is sold at many hardware stores and is great for barricading parking lots or defending yourself.

Grade 70 transport chains used by trucking and transportation companies are acceptable for use as tie down chains to tie down loads.

Grader 80, 100 & 120 is acceptable for lifting loads. The metal used in Grade 80, 100 and 120 crane rigging slings is designed to stretch and elongate but the most common grade of alloy lifting chain used for lifting loads is Grade 80.

Advantages of Using Alloy Chain Slings:

• High-strength, durable, and flexible design holds up in the harshest operating environments

• Completely repairable by replacing individual chain links or link segments

• Chain slings are easy to inspect, proof-test, and re-certify in the event they are repaired

• Can be used at relatively high temperatures and in hazardous environments where other slings would be damaged or destroyed

• Resistant to corrosion, chemicals, and UV exposure

• Not affected by dirt, oil, or grease

• Will elongate 15-20% when overloaded to give a visual indicator that they have been overloaded and need to be destroyed and removed from service

• High-strength, durable, and flexible design holds up in the harshest operating environments

• Completely repairable by replacing individual chain links or link segments

• Chain slings are easy to inspect, proof-test, and re-certify in the event they are repaired

• Can be used at relatively high temperatures and in hazardous environments where other slings would be damaged or destroyed

• Resistant to corrosion, chemicals, and UV exposure

• Not affected by dirt, oil, or grease

• Will elongate 15-20% when overloaded to give a visual indicator that they have been overloaded and need to be destroyed and removed from service

Disadvantages of Using Alloy Chain Slings:

• Very heavy – the higher the W.L.L. is, the heavier the chain will be

• Can be more expensive than wire rope or synthetic slings

• Can easily damage or crush sensitive or finished parts

• Very heavy – the higher the W.L.L. is, the heavier the chain will be

• Can be more expensive than wire rope or synthetic slings

• Can easily damage or crush sensitive or finished parts