Lifting Belt Capacity Chart & Color Code

Lifting Belt Capacity Chart & Color Code as per Indian Standards

When it comes to safe material handling, lifting belts (also called webbing slings) are a trusted choice in industries, construction sites, and warehouses. But to use them effectively, you must know how much weight each belt can lift and how to identify it quickly—this is where the capacity chart & color code system comes in.

In India, these color codes follow international norms like EN 1492-1 and are widely accepted for quick recognition and safety compliance.

Why Color Codes Matter for Lifting Belts

- Quick Identification – Workers can instantly recognize capacity without reading the tag.

- Safety Compliance – Meets Indian & International safety standards.

- Reduces Mistakes – Prevents overloading that could lead to accidents.

- Standardized System – Used globally, making it easy for cross-site work.

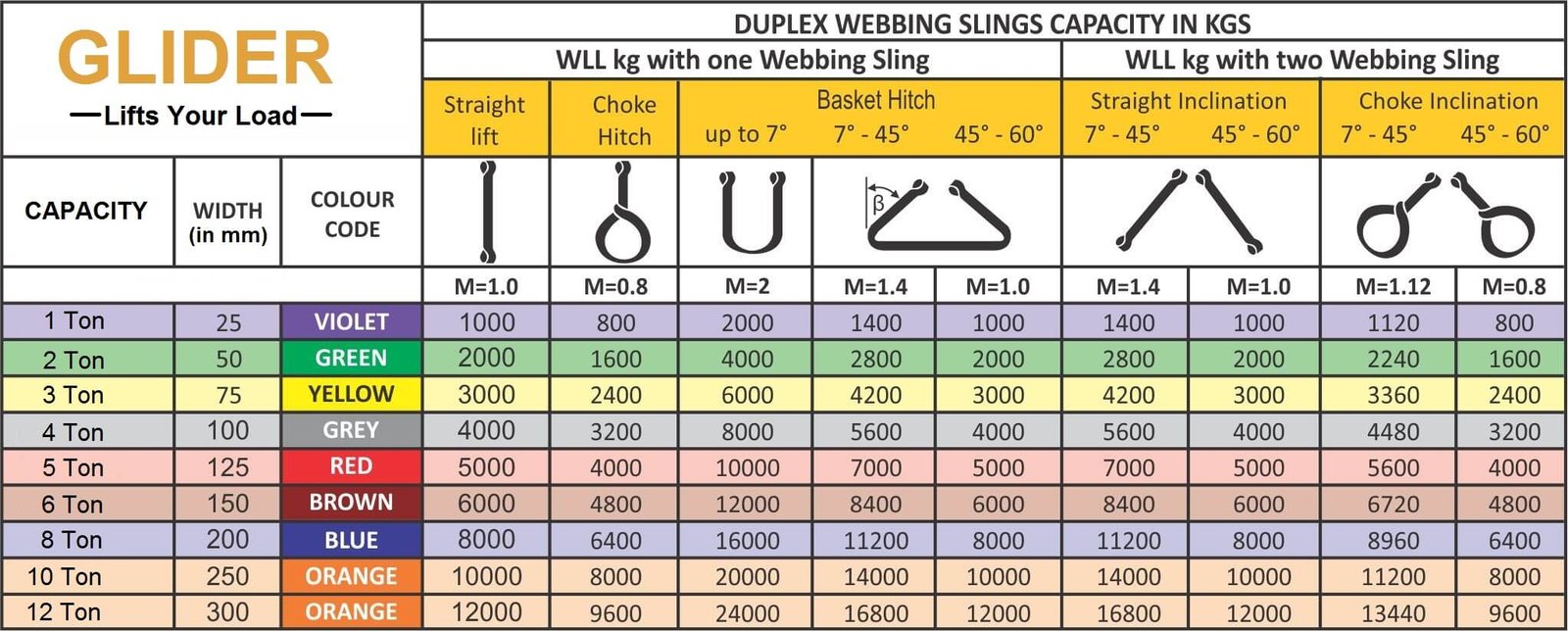

Lifting Belt Color Code Chart (as per Indian Standards)

| Color | Safe Working Load (SWL) | Width (Approx.) | Common Uses |

| Purple | 1 Ton | 25 mm | Light-duty lifting, workshop loads |

| Green | 2 Ton | 50 mm | Machinery, general industrial lifting |

| Yellow | 3 Ton | 75 mm | Construction materials, pipes |

| Grey | 4 Ton | 100 mm | Heavy equipment, fabrication units |

| Red | 5 Ton | 125 mm | Large machinery, heavy steel |

| Brown | 6 Ton | 150 mm | Industrial plant equipment |

| Blue | 8 Ton | 200 mm | Heavy-duty plant lifting |

| Orange | 10 Ton | 250 mm | Extra heavy industrial loads |

| Mostly Orange | Above 10 Ton | 2 Ply & Above | For all types of heavy loads |

Note: Always check the manufacturer’s label for exact capacity & safety factors.

Types of Lifting Belts

- Flat Webbing Slings – Flexible & lightweight, ideal for general lifting.

- Round Slings – Circular and extremely strong, used for heavy loads.

- Endless Belts – No fixed eye loops, can be used in multiple configurations.

Safety Tips While Using Lifting Belts

- Inspect before every use – Look for cuts, frays, or burns.

- Never exceed SWL – Overloading can cause sudden failure.

- Avoid sharp edges – Use corner protectors to extend belt life.

- Store properly – Keep away from sunlight, chemicals, and moisture.

- Use correct hitch type – Straight, choke, or basket lift as per requirement.

Lifting Belt Capacity at Different Hitch Configurations

| Hitch Type | Load Factor | Example |

| Straight Lift | 1.0 | SWL remains the same |

| Choke Hitch | 0.8 | 20% reduction in SWL |

| Basket Hitch (90°) | 2.0 | Doubles SWL |

| Basket Hitch (60°) | 1.73 | Increases SWL by 73% |

Images for Better Understanding

Conclusion

Following the lifting belt capacity chart & color code is not just about compliance—it’s about protecting people, equipment, and productivity. By recognizing these codes and working within safe load limits, you ensure smooth operations and zero downtim