WIRE ROPE SLING MANUFACTURER

‘Modi Wire Rope Sling’ Manufacturer

Need Help in Buying Decision? Call us on 7015580851 and we are here to suggest you which type of Wire Rope Sling will go best for your work.

'MODI WIRE ROPE SLING' is a registered trademark of Modi Lifting Solutions

Modi Lifting Solutions are the Steel Wire Rope Sling Manufacturer with the brand name 'Modi Wire Rope Sling' and manufactures Wire Rope Slings with Hydraulic Splicing Technique using aluminium ferrule under the IS Standards. With in-house testing facility we completely assures that each item we manufacture leaves with all quality checks. We also have a large stock of wire rope and fittings to choose from. Need something more specific? No problem, we can even design bespoke fittings and create tailored solutions on request.

Wire Rope Slings are popular in construction, automotive, oil and gas, and general manufacturing industries where a variety of heavy loads and rugged conditions exist. They’re also very popular in steel mills and forging facilities where the durability of the rope is really put to the test.

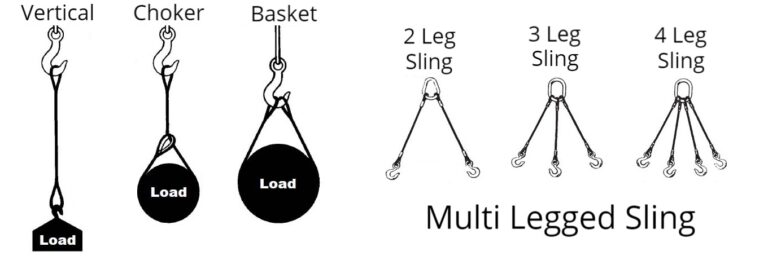

Wire Rope Slings are available in single-leg or multi-leg assemblies and can be used in a variety of hitches including vertical, choker, and basket hitches. The Design Factor for wire rope slings is a 5:1 ratio, meaning the breaking strength of the sling is five times higher than the rated Working Load Limit (W.L.L).

Types of Loops on the ends of Wire Rope Sling which can be customized in different ways: Soft Eye Loop, With Thimbles, With Thimble & Hooks, With Double Ferrules, Flemish Eye and it can be customized in many more ways as per requirement.

VERTICAL, or straight, attachment is simply using a sling to connect a lifting hook to a load.

CHOKER hitches reduce lifting capability of a sling since this method of rigging affects ability of the wire rope components to adjust during the lift.

BASKET hitches distribute a load equally between the two legs of a sling … within limitations described above.

MULTI LEGGED SLING have 2 or more than 2 Legs attached to a single Master Ring and have number of slings that can be attached to a load on edges.

• Lower initial cost and lighter in weight than alloy chain slings

• High strength and flexibility in a smaller diameter design

• Different designs and constructions of wire rope provide: Strength, Flexibility, Abrasion resistance, Fatigue resistance, Corrosion resistance

• Braided or multi-part slings: More resistant to kinking than single-part slings, Have high flexibility, Snug up tightly around the load in choker hitches, Quickly regain their original shape after a lift

• Can be used in vertical, choker, and basket hitches

• If the wire rope on sling bridles is damaged, the hardware (master links and hooks) can be re-used—provided that the hardware itself is not damaged

• Low strength to weight ratio

• Construction can make it difficult to inspect—especially in and around the core

• Misuse or abuse can cause kinking, crushing, or abrasion—resulting in structural damage and loss of strength

• Not repairable – if it is removed from service, best practices should be followed to destroy and dispose of the sling

• Can be susceptible to internal and external corrosion

• Trade-offs exist between the design and construction: a rope that is more abrasion resistant will offer less fatigue resistance—and vice versa

• Steel core slings should never be used at temperatures above 400°F or below -40°F