Wire Rope Sling Load Capacity Chart

The Complete Guide to Wire Rope Sling Load Capacity Chart (8mm to 80mm)

When it comes to heavy lifting in industrial settings, wire rope slings are an indispensable tool. Whether you’re in construction, shipping, or manufacturing, understanding the exact load capacity of your wire rope sling is essential for safe and efficient lifting. This blog will provide a comprehensive lifting load chart for wire rope slings ranging from 8mm to 80mm, detailing the load capacities for different angles and hitch types.

What Are Wire Rope Slings?

Wire rope slings are constructed from multiple strands of steel wire twisted together to form a strong, flexible lifting tool. They are known for their durability, resistance to abrasion, and ability to handle extremely heavy loads. These slings are used in various applications, from hoisting machinery to securing cargo, and are crucial for safe lifting operations.

Comprehensive Lifting Load Chart (8mm to 80mm)

Below is an extensive lifting load chart for wire rope slings, covering diameters from 8mm to 80mm. The chart includes the working load limits (WLL) for different hitches—vertical, choker, and basket—as well as for different lifting angles.

| Wire Rope Diameter (mm) | Vertical Hitch WLL | Choker Hitch WLL | Basket Hitch WLL | 30° Angle WLL | 45° Angle WLL | 60° Angle WLL |

|---|---|---|---|---|---|---|

| 8 mm | 0.8 tons | 0.6 tons | 1.6 tons | 0.4 tons | 0.6 tons | 0.7 tons |

| 9 mm | 1.0 tons | 0.8 tons | 2.0 tons | 0.5 tons | 0.7 tons | 0.9 tons |

| 10 mm | 1.2 tons | 0.9 tons | 2.4 tons | 0.6 tons | 0.8 tons | 1.0 tons |

| 11 mm | 1.5 tons | 1.1 tons | 3.0 tons | 0.7 tons | 1.1 tons | 1.3 tons |

| 12 mm | 1.8 tons | 1.4 tons | 3.6 tons | 0.9 tons | 1.3 tons | 1.5 tons |

| 13 mm | 2.1 tons | 1.6 tons | 4.2 tons | 1.0 tons | 1.5 tons | 1.8 tons |

| 14 mm | 2.5 tons | 1.9 tons | 5.0 tons | 1.3 tons | 1.8 tons | 2.1 tons |

| 16 mm | 3.2 tons | 2.4 tons | 6.4 tons | 1.6 tons | 2.3 tons | 2.8 tons |

| 18 mm | 4.1 tons | 3.1 tons | 8.2 tons | 2.1 tons | 2.9 tons | 3.5 tons |

| 20 mm | 5.0 tons | 3.7 tons | 10.0 tons | 2.5 tons | 3.5 tons | 4.3 tons |

| 22 mm | 6.2 tons | 4.6 tons | 12.4 tons | 3.1 tons | 4.3 tons | 5.3 tons |

| 24 mm | 7.5 tons | 5.6 tons | 15.0 tons | 3.8 tons | 5.2 tons | 6.5 tons |

| 25 mm | 7.8 tons | 5.9 tons | 15.6 tons | 3.9 tons | 5.5 tons | 6.7 tons |

| 26 mm | 8.4 tons | 6.3 tons | 16.8 tons | 4.2 tons | 5.9 tons | 7.2 tons |

| 28 mm | 10.0 tons | 7.5 tons | 20.0 tons | 5.0 tons | 7.1 tons | 8.7 tons |

| 30 mm | 11.5 tons | 8.6 tons | 23.0 tons | 5.8 tons | 8.2 tons | 10.0 tons |

| 32 mm | 12.8 tons | 9.6 tons | 25.6 tons | 6.4 tons | 9.1 tons | 11.1 tons |

| 34 mm | 14.5 tons | 10.9 tons | 29.0 tons | 7.2 tons | 10.3 tons | 12.6 tons |

| 36 mm | 16.2 tons | 12.1 tons | 32.4 tons | 8.1 tons | 11.4 tons | 14.0 tons |

| 38 mm | 18.0 tons | 13.5 tons | 36.0 tons | 9.0 tons | 12.7 tons | 15.4 tons |

| 40 mm | 20.0 tons | 15.0 tons | 40.0 tons | 10.0 tons | 14.1 tons | 17.3 tons |

| 44 mm | 24.0 tons | 18.0 tons | 48.0 tons | 12.0 tons | 16.9 tons | 20.7 tons |

| 48 mm | 28.5 tons | 21.3 tons | 57.0 tons | 14.3 tons | 20.1 tons | 24.6 tons |

| 50 mm | 31.2 tons | 23.4 tons | 62.4 tons | 15.6 tons | 22.0 tons | 26.9 tons |

| 52 mm | 33.5 tons | 25.1 tons | 67.0 tons | 16.8 tons | 23.6 tons | 28.9 tons |

| 56 mm | 40.0 tons | 30.0 tons | 80.0 tons | 20.0 tons | 28.2 tons | 34.6 tons |

| 60 mm | 45.0 tons | 33.7 tons | 90.0 tons | 22.5 tons | 31.7 tons | 38.9 tons |

| 63 mm | 50.0 tons | 37.5 tons | 100.0 tons | 25.0 tons | 35.3 tons | 43.3 tons |

| 65 mm | 54.0 tons | 40.5 tons | 108.0 tons | 27.0 tons | 38.2 tons | 46.8 tons |

| 70 mm | 62.0 tons | 46.5 tons | 124.0 tons | 31.0 tons | 43.9 tons | 53.8 tons |

| 76 mm | 75.0 tons | 56.3 tons | 150.0 tons | 37.5 tons | 53.1 tons | 65.1 tons |

| 80 mm | 80.0 tons | 60.0 tons | 160.0 tons | 40.0 tons | 56.4 tons | 69.2 tons |

How Load Conditions and Angles Affect Lifting Capacity

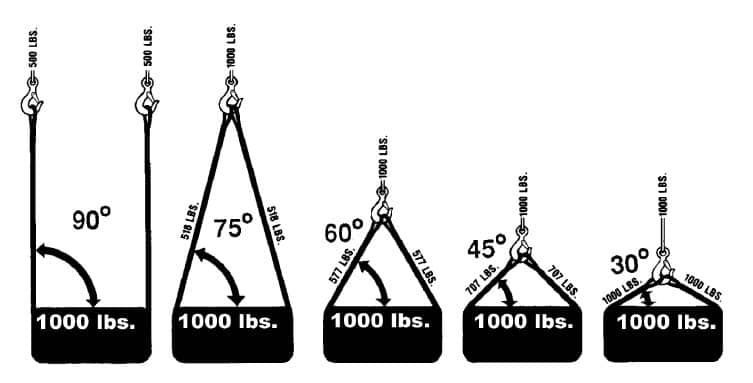

The lifting capacity of a wire rope sling isn’t just determined by its diameter. The angle of the lift and the type of hitch also play a critical role. Here’s how these factors influence the working load limit (WLL):

Vertical Hitch: This method involves lifting directly from above. It offers the maximum WLL, making it ideal for straightforward lifts.

Choker Hitch: This involves wrapping the sling around the load and securing it to itself. It reduces the WLL by approximately 20-25%, depending on the tightness of the choke.

Basket Hitch: This method doubles the WLL compared to a vertical hitch, as the load is evenly distributed. It’s excellent for balancing heavy loads.

Angle Impact: The smaller the angle between the legs of the sling and the load, the greater the stress on the sling. For instance, at a 30° angle, the WLL can be reduced by 50%, whereas at a 60° angle, the reduction is less significant, around 13%.

Practical Applications of Wire Rope Slings

Wire rope slings are used across various industries, each with unique demands:

- Construction: Lifting steel beams, concrete blocks, and prefabricated structures.

- Shipping: Handling cargo containers and heavy machinery during loading and unloading.

- Manufacturing: Moving large pieces of equipment or materials within a production facility.

- Oil and Gas: Lifting and securing drilling equipment and other heavy tools.

Visual Guide to Wire Rope Slings

[Image 1: Wire Rope Sling Lifting a Heavy Load]

A visual demonstration of a wire rope sling being used in an industrial setting, emphasizing its strength and versatility.

[Image 2: Illustration of Different Hitch Types]

A clear diagram showing vertical, choker, and basket hitches, explaining how each method impacts the WLL.

[Image 3: Angle Impact on WLL]

A detailed illustration of how different lifting angles affect the working load limit of a wire rope sling.

Conclusion

Wire rope slings are essential tools in heavy lifting operations. Knowing the exact lifting load capacity for each diameter and understanding how different load conditions and angles affect these capacities are crucial for safe and efficient lifting. Whether using an 8mm sling for lighter loads or a 80mm sling for massive industrial tasks, this comprehensive guide provides all the information needed to handle your lifting operations with confidence.